Unlocking the Potential of LED Displays: A Step-by-Step Guide from Basics to Advanced Understanding

Introduction

In this article, you will learn comprehensive knowledge about LED displays, starting from the concept of LED chips to the composition of LED displays and their parameters. Combined with our experience in the LED display industry, it will help you understand the industry from a practical point of view, and help you transform from a novice in the LED display industry to a professional practitioner.

If you are a newcomer to the LED display industry or interested in learning related knowledge, this article is highly suitable for you.

1. What is LED?

Understanding LED is crucial when it comes to LED display screens. It forms the foundation of LED display technology, where countless LED bulbs illuminate and go dim to create various visible images.

Voltage: LED uses a low-voltage power supply, and the voltage of a single LED is between 1.9-4V, which is a safer power supply than using a high-voltage power supply.

Efficacy: High luminous efficiency, currently the highest luminous efficiency in the laboratory has reached 251 lm/w, which is currently the lighting product with the highest luminous efficiency.

Shock resistance: LED is a solid-state light source. Due to its particularity, it has shock resistance that other light source products cannot match.

Stability: LEDs maintain 70% of their initial luminous flux after 100,000 hours of operation.

Response time: The response time of LEDs is nanosecond level, which is the product with the fastest response time among all light sources at present.

Environmental protection: no metal mercury and other substances harmful to the environment.

Color: The band of LED is quite narrow, and the color of the light emitted is pure, without variegated light, covering all the wavelength bands of visible light, and can be combined into any desired visible light by R\G\B.

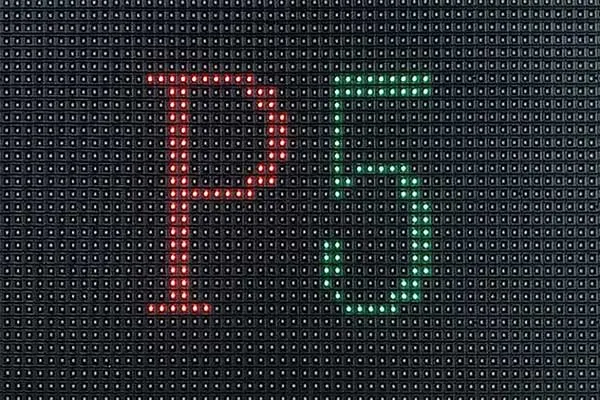

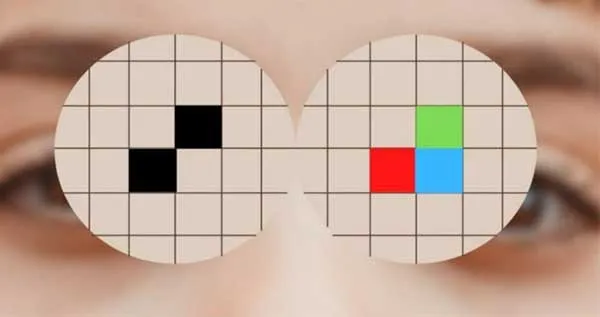

2. What is a Pixel?

1R: Indicates one single red LED.

2R1G: Indicates two red LEDs and one green LED.

2R1G1B: Indicates two red LEDs, one green LED, and one blue LED. (This means that a pixel has four individual lights.)

Understanding the concept of pixels is essential to comprehend how LED displays work, as they form the basis for creating images on the screen.

For example, for a P5 modular, the size is 320mm*160mm, and a single modular has 64*32 dots(pixels)

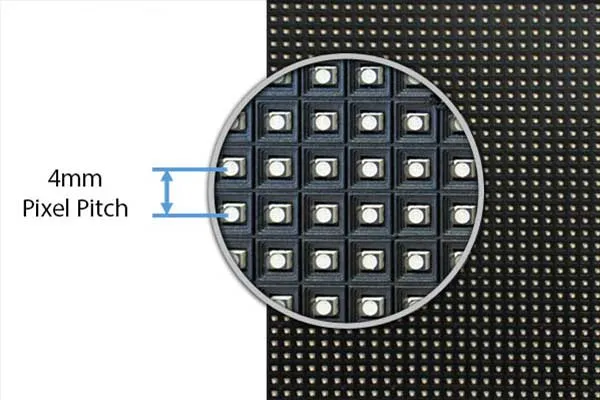

3. What is Pixel Pitch?

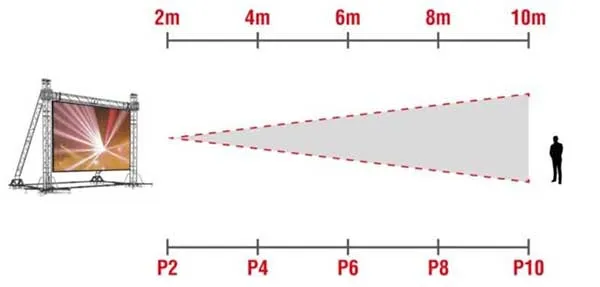

Pixel pitch is a crucial factor as it directly affects the viewing distance and clarity of the screen. The optimal viewing distance for a screen is determined by the value of the pixel pitch.

For example, for a P4 LED Display, the Pixel Pitch is 4mm.

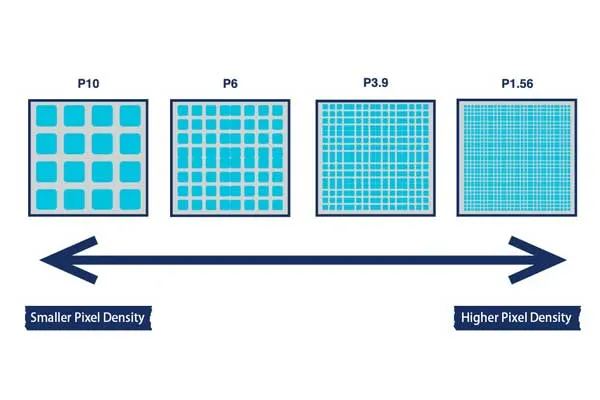

4. What is Pixel Density?

Since pixel pitch reflects the spatial distance between two pixels, a smaller pixel pitch means a smaller space between pixels. In other words, it signifies higher pixel density and a higher screen resolution.

However, it is important to note that while higher pixel density can enhance visual quality, it does not necessarily mean that a smaller pixel pitch is the ideal choice in all circumstances. Higher pixel density is intended to provide a closer viewing distance. At larger viewing distances, higher pixel density loses its visual advantage and can increase costs.

Therefore, the selection of pixel density depends on factors such as the intended viewing distance, desired visual quality, and budget considerations.

Pixel Density = (1000mm / Pixel Pitch mm) * (1000mm / Pixel Pitch mm) dots/m²

For example: The pixel density of P2.5 is 160,000 dots/m². For a display area of 1 square meter, the resolution of P2.5 is 400 * 400 pixels.

Calculation process of pixel density:

The unit of pixel density is dots/m².

1 meter = 1000mm Since P2.5 represents a pixel pitch of 2.5mm,

we have: Pixel Density = (1000/2.5mm) * (1000/2.5mm) = 400 * 400 = 160,000 dots/m²

Here are some examples of full-color LED display models and their corresponding pixel density (number of pixels) in dots per square meter:

- P2 Indoor Fine-Pitch Full-Color LED Display = 250,000 dots/m²

- P2.5 Indoor High-Definition Full-Color LED Display = 160,000 dots/m²

- P3 Indoor Full-Color LED Display = 111,111 dots/m²

- P4 Indoor Full-Color LED Display = 62,500 dots/m²

- Outdoor P4 Full-Color LED Display = 62,500 dots/m²

- Outdoor P5 Full-Color LED Display = 40,000 dots/m²

- Outdoor P6 Full-Color LED Display = 27,800 dots/m²

- Outdoor P8 Full-Color LED Display = 15,625 dots/m²

- Outdoor P10 Full-Color LED Display = 10,000 dots/m²

5. What is an LED Display Modular?

In simple terms, an LED display module refers to a printed circuit board (PCB) that is equipped with ICs, LED chips, and other components through soldering. Each module has different size specifications depending on the model. For example, the dimensions of a P2 module could be 128×256, P2.5 module sizes could be 160×160 or 320×160, and P3 module sizes could be 192×192, and so on. These modules play a crucial role in creating functional LED display screens through simple assembly.

| Pixel Pitch | LED Modular Size |

| P1.25, P1.53, P1.66, P1.8, P2, P2.5 | 320*160mm |

| P3, P4, P5, P6 | 256*128mm, 192*192mm |

| P8, P10, P15, P20 | 160*160mm, 256*128mm |

Currently, in the market, LED display modular sizes are mainly 320*160mm, 160*160mm, 256*128mm, 192*192mm, and so on.

Among these, the 320*160mm modular is widely used, especially for indoor LED displays. This size is popular for two reasons: first, its aspect ratio is 2:1, and second, the larger module size makes it more convenient during LED cabinet production and installation. It reduces the number of module splices, resulting in a smoother surface for the entire LED display.

6. What is LED Screen Cabinet (LED Display Cabinet)

The LED screen cabinet (LED display cabinet) refers to the external structure used for mounting and protecting LED display modules (or unit boards). Typically, it is made of metal materials such as aluminum alloy. The LED display cabinet provides a stable support structure and safeguards the display modules, while also assisting in heat dissipation and circuit protection.

The cabinet serves as the fundamental framework for various components. The receiving card, power supply, HUB card, and unit boards (modules) are all installed on the cabinet, forming the basic display unit of an LED display screen. Additionally, the cabinet is designed with power and signal interfaces for easy connectivity.

Please note that “unit boards” “modules” and “LED display panel” all are mentioned as interchangeable terms for the LED display components.

The following are common led display cabinet sizes:

For fixed installations, common sizes for iron LED display cabinets include 1024mm×1024mm, 960mm×960mm, 768mm×768mm, 576mm×576mm, and 512mm×512mm.

For rental purposes, commonly used die-cast aluminum LED cabinets come in sizes like 500mm×500mm and 500mm×1000mm.

7. What is an LED Screen (LED Display Screen)?

An LED screen is a flat panel display consisting of individual LED display modules that are used to present various types of information, such as text, images, videos, and more. It is a screen composed of an array of LED devices controlled in a specific manner.

LED displays integrate microelectronics, computer technology, and information processing to deliver vibrant colors, wide dynamic range, high brightness, long lifespan, and reliable operation. They find extensive applications in commercial media, cultural performances, sports arenas, information dissemination, news broadcasting, securities trading, and more, catering to diverse environmental requirements.

Here are the different types of LED displays:

- Rental LED Display: Suitable for theme parks, bars, auditoriums, theaters, events, and building facades.

- Fine Pitch LED Display: Commonly used in airports, schools, transportation, and esports competitions.

- Transparent LED Display: Used in advertising, large shopping malls, corporate showrooms, and exhibitions.

- Creative LED Display: Ideal for advertising, sports stadiums, conference centers, real estate, and stages.

- Fixed Installation LED Display: Often used for TV shows, VCD/DVD playback, live events, and advertising.

- Single-Color LED Display: Widely used in bus stations, banks, shops, and docks.

- Dual-Color LED Display: Mainly used in subways, airports, commercial centers, wedding studios, and restaurants.

- Full-Color LED Display: Suitable for office buildings, high-speed railway stations, commercial advertising, information dissemination, and exhibition centers.

- Indoor LED Display: Commonly used in hotel lobbies, supermarkets, KTVs, commercial centers, and hospitals.

- Outdoor LED Display: Used for creating a festive atmosphere, promoting corporate products and advertisements, and conveying information. Often found in buildings, advertising industry, enterprises, and parks.

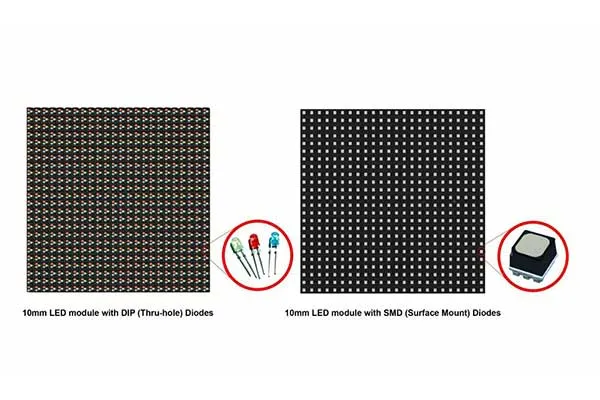

8. What is DIP? What is a DIP LED Display?

DIP stands for Dual In-Line Package, a type of integrated circuit (IC) packaging. It features a rectangular shape with two parallel rows of metal pins called dual inline pins. Components in DIP packaging can be soldered onto printed circuit boards or inserted into DIP sockets.

A DIP LED display refers to an LED display screen made using DIP technology. DIP LEDs are encapsulated using a molding process. Liquid epoxy resin is injected into the LED mold cavity, and pre-soldered LED leads are inserted. After curing the epoxy resin in an oven, the LED is released from the mold and takes its final shape.

DIP LED displays are popular due to their relatively simple manufacturing process, low cost, and higher market share. They are larger in size and can be manually or machine-inserted. DIP LEDs offer high brightness, making them suitable for outdoor LED displays where waterproofing is often required.

9. What is SMT Module? What are its advantages and disadvantages?

SMT Module, also known as surface-mount technology, involves soldering SMT-packaged LEDs onto the surface of a PCB without the need for the LED pins to pass through the board. The modules created using this process are called surface mount modules or SMT modules.

Advantages: Wide viewing angle, smooth image display, excellent visual performance, high pixel density, suitable for indoor viewing. High pixel density, making it suitable for indoor viewing.

Disadvantages: Lower brightness compared to other technologies, LEDs may have inadequate heat dissipation.

10. What is Semi-Surface Mount Module (SSM)? What are its advantages and disadvantages?

Semi-Surface Mount Module, also known as plug-in LED or quasi-SMT, is a type of product where the LED is encapsulated into a rectangular shape, and the red, green, and blue LEDs are combined to form a pixel and module. The assembly process involves passing the LED pins through the PCB for soldering.

Advantages: Shares some characteristics with SMT, utilizing similar surface-mount LED packaging, but has the pin-through-hole soldering process like DIP. It achieves some benefits of surface-mount technology.

Disadvantages: Compared to full SMT, semi-surface mount technology may have inferior color performance. It is considered a transitional technology and is now mostly phased out.

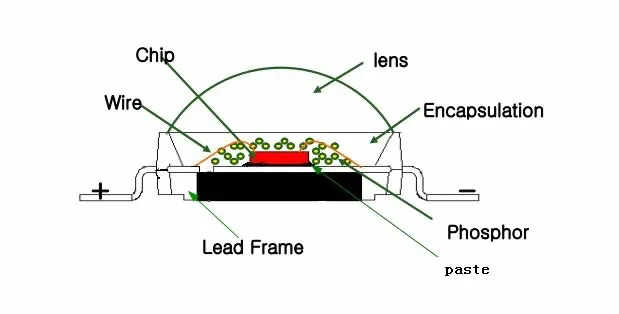

11. What is COB Packaging? What are its advantages and disadvantages?

COB packaging, also known as chip on board, involves attaching bare LED chips to a substrate using conductive or non-conductive adhesive, followed by wire bonding for electrical connections. COB packaging is a no-bracket technology, eliminating the need for bracketed pin soldering. Each LED chip and bonding wire are encapsulated tightly within epoxy resin, leaving no exposed elements.

Advantages: COB packaging offers significant advantages in efficiency, cost, and reliability compared to traditional SMD single LED packaging.

Disadvantages: Although COB packaging is widely used in lighting applications, it is still in the developmental stage for LED display screens. Challenges remain in areas such as optical and ink color consistency, and achieving mass production is still difficult, leading manufacturers to adopt a cautious approach.

12. What is GOB Packaging? What are its advantages?

GOB encapsulation technology is a packaging technique developed to address LED chip protection. It utilizes advanced transparent materials to encapsulate both the PCB substrate and LED chips, providing effective protection.

Essentially, it adds an additional protective layer to the original LED module, achieving high-level protection such as waterproof, moisture-proof, impact-resistant, scratch-resistant, static-resistant, salt-resistant, oxidation-resistant, blue light-resistant, and shock-resistant.

The advantages of GOB encapsulation technology are as follows:

GOB offers high protection for LED displays, providing eight protections: waterproof, moisture-proof, impact-resistant, dust-proof, corrosion-resistant, blue light-resistant, salt-resistant, and static-resistant. Additionally, it does not negatively impact heat dissipation or brightness. Rigorous testing has shown that the encapsulation material even contributes to heat dissipation, reducing LED chip failure rates and enhancing display stability, leading to prolonged service life.

Through the GOB process, the previously granular pixel points on the LED module surface transform into a seamless flat panel, resulting in a transition from point source to surface source. This achieves more uniform light emission, clearer and more transparent display effects, and significantly improved viewing angles (near 180° horizontally and vertically). It effectively eliminates moiré patterns, enhances product contrast, reduces glare and eye strain, thus alleviating visual fatigue.

13. What is "three-in-one" (Tri-color LED)?

Advantages: Excellent display performance, achieving vibrant and colorful visual effects, making it suitable for color LED displays with outstanding display quality.

Disadvantages: The manufacturing process is complex, and repair can be challenging due to multiple integrated LED chips in one package. Consequently, it results in higher production costs.

14. What is Luminous Brightness of LED Display?

Luminous Brightness of an LED display refers to the intensity of light emitted per unit area, measured in CD/square meter. In simple terms, it represents the light intensity emitted by a one-square-meter LED display.

Different environments have varying brightness requirements for LED displays:

● Indoor LED Display: >800 CD/square meter

● Semi-indoor LED Display: >2000 CD/square meter

● Outdoor LED Display (facing north): >4000 CD/square meter

● Outdoor LED Display (facing south): >8000 CD/square meter

The above standards are theoretical values, and the LED screen’s brightness can be adjusted based on visual perception and surrounding environment. Typically, outdoor full-color LED screens facing south require brightness above 6500 CD/square meter and facing north above 5000 CD/square meter, outdoor single-color LED message boards require brightness above 1500 CD/square meter, indoor full-color LED screens require brightness above 1200 CD/square meter, and indoor single-color LED screens require brightness above 280 CD/square meter to meet the requirements.

15. What is the Brightness Level of an LED Display?

The brightness level of an LED display refers to the number of manual or automatic adjustments between the lowest and highest brightness settings of the entire screen.

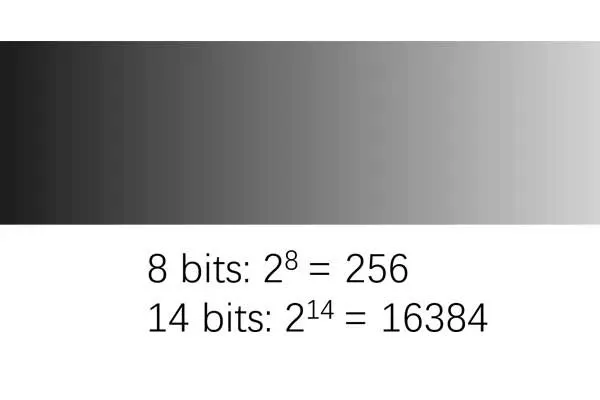

16. What is the Gray Scale Level of an LED Display?

The gray scale level of an LED display refers to the number of technical processing steps between the darkest and brightest states at the same brightness level. Higher gray scale allows for more color variations in the image, resulting in smoother color transitions and a clearer, more vivid overall display effect. In low gray scale states, achieving such display effects becomes challenging.

With higher gray scale levels, the display can present richer colors and finer details, enhancing the visual experience. Commonly, LED displays have four levels of gray scale: 256 levels, 1024 levels, 4096 levels, and 16384 levels.

In general use, LED displays with 256 and 1024 gray scale levels (8-bit or 10-bit systems) are more common, while commercial or broadcast-grade products may use LED displays with 4096 or even higher gray scale levels.

17. What is the Maximum Brightness of an LED Display?

The maximum brightness of an LED display refers to the brightness level of each primary color (Red, Green, and Blue) when the display operates at its highest brightness and maximum gray scale level, given a certain ambient illuminance.

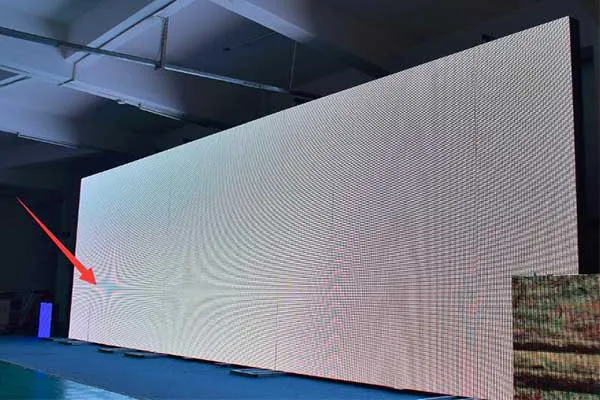

18. What is Moiré Pattern in LED Displays?

Moiré pattern in LED displays refers to the irregular water-like ripples that appear when capturing images or videos of full-color LED screens. In physics, these ripples are known as “Moiré patterns.”

In simple terms, Moiré patterns occur when two grid-like pixel arrays interfere with each other, causing the grid’s bright and dark parts to overlap and create a wave-like visual effect. This phenomenon is caused by the interaction between the LED display’s refresh rate and the camera’s aperture and focal length.

19. What is PCB?

PCB stands for “Printed Circuit Board,” which is used to mechanically support and electrically connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

20. What is the LED display unit board specification?

The LED display unit board specification refers to the size of the unit board, usually expressed as the length multiplied by the width, measured in millimeters. (For example, 320×160)

21. What is the resolution of the LED display unit board?

The resolution of the LED display unit board refers to how many pixels are on one unit board, usually expressed as the number of rows multiplied by the number of columns of pixels. (For example, 128×64)

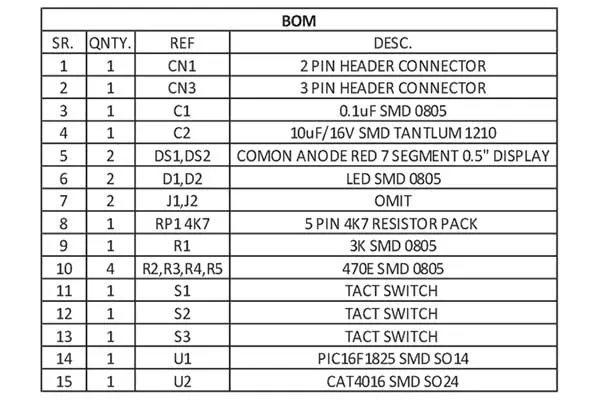

22. What is BOM?

BOM stands for “Bill of Materials,” which is a document that describes the product’s structure in a data format recognizable by computers. It serves as the primary file in an ERP system, allowing the system to identify the product structure and act as a link for communication across various business operations. The five main types of BOM in an ERP system are Indented BOM, Summarized BOM, Phantom BOM, Cost BOM, and Planning BOM.

23. What is white balance, what is white balance adjustment?

White balance refers to the balance of white color, specifically the balance of the brightness ratios of RGB (Red, Green, Blue) colors. The adjustment of the brightness ratios of RGB colors and the white point coordinates is called white balance adjustment.

24. What is contrast?

Contrast is the ratio between the maximum brightness of an LED display and the brightness of the background under certain ambient illumination.

25. What is color temperature?

Color temperature refers to the temperature of a light source when its emitted color matches that of a black body radiating at a specific temperature.

LED color temperature is measured in absolute temperature units Kelvin (K). As a standard black body is heated, its color changes from deep red to light red, then to orange-yellow, white, and finally to blue. When a light source matches the color of the black body at a specific temperature, that temperature is known as the color temperature of the light source.

26. What is color deviation?

Color deviation in LED displays refers to the observable differences in colors produced by the combination of red, green, and blue LEDs, as these three colors are made from different materials and have varying spectral distributions. When observing LEDs from certain angles, their colors may appear altered. Human eyes have a better ability to judge the true colors of real images, such as movie scenes, compared to computer-generated images.

27. What is frame rate?

Frame rate is a property of video files, indicating the number of times per second the frames of the video are updated, measured in Hertz (Hz). In other words, frame rate represents how many frames of the video are shown per second. Due to the persistence of human vision, when the frame rate reaches a certain level, the discrete frames appear as continuous. Frame rate is an important indicator of video continuity.

28. What is refresh rate?

Refresh rate refers to the number of times the display screen repeats the display of an image within a unit of time, measured in Hertz (Hz). It is an important indicator of LED display screen stability and flicker-free performance. The refresh rate is an inherent parameter of the LED display screen itself. A higher refresh rate reduces the perception of flickering and improves image clarity, while a lower refresh rate may lead to flickering and jittering on the screen.

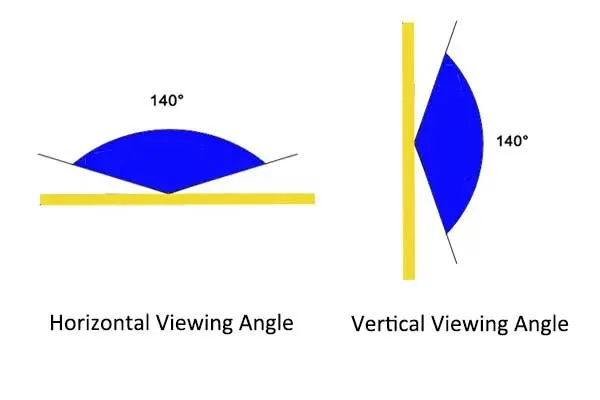

29. What is Viewing Angle? What is Viewable Angle? What is Optimal Viewing Angle?

Viewing Angle refers to the angle at which the brightness decreases to half of the LED display’s normal brightness along the normal direction. It is the angle between two observing directions on the same plane and the normal direction, divided into horizontal and vertical viewing angles.

Viewable Angle is the angle at which one can just see the content on the display screen, relative to the display screen’s normal direction.

Optimal Viewing Angle is the angle at which the content on the display screen is seen most clearly, without color distortion. It is the angle between the clearest observing direction and the normal direction of the display screen.

30. What is optimal viewing distance?

The optimal viewing distance is the vertical distance from the screen where the content on the display can be seen completely, without color distortion, and with the clearest image quality. It refers to the distance at which the viewer can have the best viewing experience in terms of clarity and color accuracy.

31. What is mean of the dead pixel? How many types?

A “dead pixel,” also known as a “stuck pixel” or “blinking pixel,” is a type of malfunctioning pixel on an LED display where its emission state doesn’t match the control signal. Dead pixels are categorized into three types: stuck-off (or dark) pixels, stuck-on (or bright) pixels, and blinking pixels.

Note: The term “blinking pixel” may refer to a pixel that exhibits intermittent behavior, switching between on and off states, causing it to flicker.

32. What is a static drive? What is a scanning driver? What is the difference between them?

Static drive refers to the control method where there is “point-to-point” control from the output pin of the driver IC to the individual pixel. Scanning drive, on the other hand, involves “point-to-column” control from the output pin of the driver IC to the pixel, requiring a row control circuit.

By examining the driver board, it is evident that static drive does not need a row control circuit, which leads to higher costs but better display performance, stability, and less brightness loss. In contrast, scanning drive requires a row control circuit, resulting in lower costs but inferior display performance and greater brightness loss.

33. What is a constant current drive? What is constant voltage drive?

Constant current refers to the driver IC outputting a constant current value within the allowed working environment as specified during design. Constant voltage, on the other hand, means the driver IC outputs a constant voltage value within the allowed working environment as specified during design.

In constant current drive, the power supply output provides a constant current under the allowed load conditions, which remains unchanged with load variations. On the other hand, constant voltage drive ensures a constant voltage output under the allowed load conditions, which also remains unaffected by load changes.

Constant current drive is typically suitable for parallel LED circuits and is commonly used in low-power LED modules and light strips. On the other hand, constant voltage drive is usually suitable for series LED circuits and is widely used in high-power LEDs and premium low-power products.